An important factor in promoting customers’ research and development is the timely implementation of testing at affordable rates and at the necessary times.

Through offering backup for customers’ battery R&D activities, we accelerate their research and development and enable flexible operation of management resources.

| For Single Cell | For Module | For Pack |

|---|---|---|

| 5V | 50V | 100V |

| 10〜600A | 200〜300A | 400A |

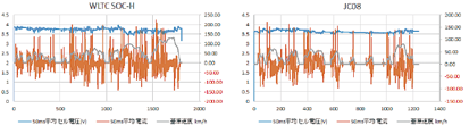

※Results of running simulation

※Results of running simulation